REDATS H-390 double action hydraulic press 50T

- New press in our store! Check out the hydraulic press with a double pump, which has a pressure of 50 tons.

How does it differ from the H-380 model?

First of all, the pressure. It is 50 tons (20 tons more)! Thanks to this, it can handle larger parts and more difficult work, which increases its versatility in the car services.

The working shelf is almost 155 mm wider (and is 695 mm)! This gives your customer more room for large parts, making it easier to place them stably and process them precisely.

The entire press is 60 mm lower (its height is 1690 mm), so it will fit more easily in car sercices with limited height, which increases its versatility in different work spaces.

The weight of the machine has also increased, and by 115g (the current weight is 240kg). This will make the press more stable during operation, which minimizes the risk of the device shifting and increases the safety of use.

What else is worth knowing about this press?

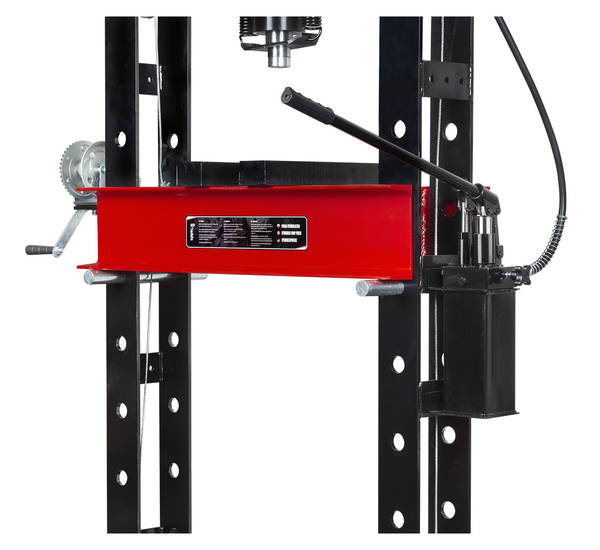

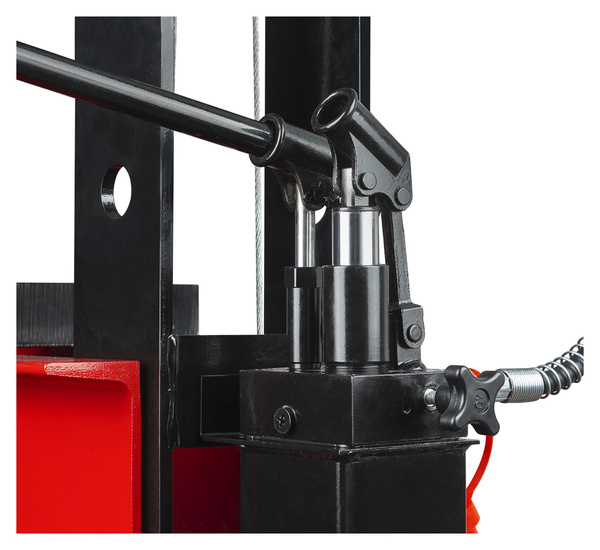

Double pump with different strokes - easily adjustable

This press has a double pump with different strokes - quick and slow stroke. It allows for an easier control over the tool.

Application

This is an essential addition for any tyre service and car repair professional. It might be used for or pressing, forming and bending jobs.

Exceptional working comfort

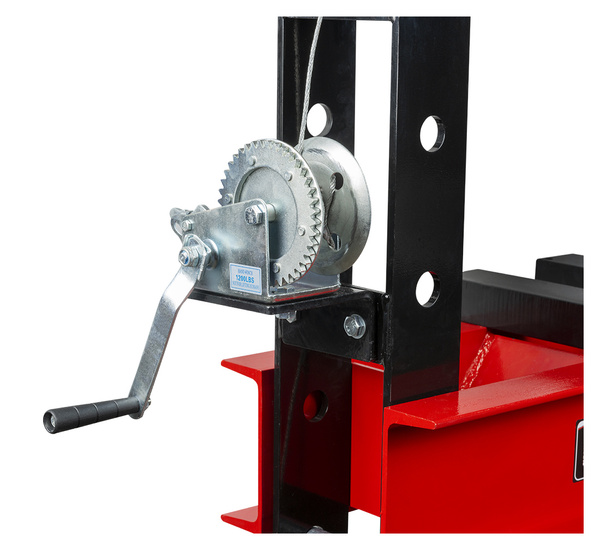

This press has a working range of 100-1000 mm. The worktop can be set in one of 8 positions. The max. capacity is 50 tons.

Reliability for years

Top quality framework, along with proven steel means trouble-free operation for many years. The framework is thicker than in the 20T press. This provides for an even more trouble-free work throughout the years.

Easy to read parameters

This press has an easy-to-read manometer, showing the pressure in tons - it allows for an easier reading of pressure values at any time.

Safety is important

The unit includes a single-acting actuator. It is designed for raising the load only, not holding it up.

What does it mean for your clients?

Whenever the load is up, there must be some support for it. The unit itself cannot be used as support for the load.

Why shouldn’t the load lay on the actuator?

The weight of the load would lead to a sudden drop down of the actuator. It also leads to quicker wear-out.

Expert's review:

Artur: The 50-ton, dual pump, and table winch deliver plenty of power. Plus, the equipment is quick and easy to operate.

Entity data

23-114 Jabłonna k/Lublina

Poland

sklep@redats.com