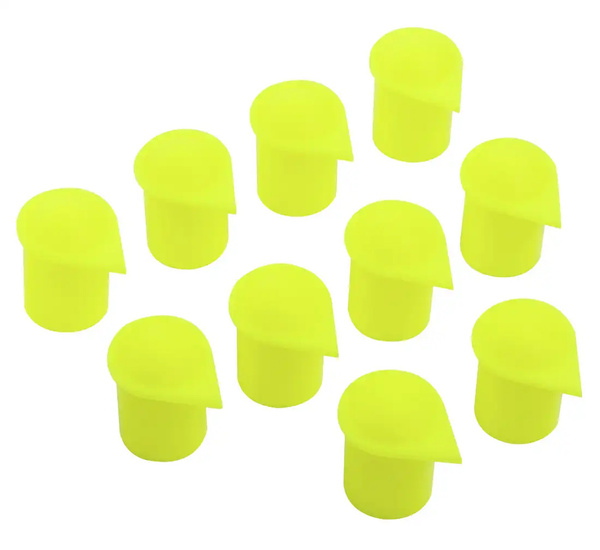

Dust Cap Covers – Wheel Nut Loosening Indicator for Hubcaps 24mm – 10 pcs

Dust Cap Covers (CheckPoint) – wheel nut covers with rotation indicators.

An affordable and simple way to improve road transport safety.

Dust Cap covers operate on the same principle as the CheckPoint system. Additional advantages of Dust Cap indicators include:

- A sealed cover that prevents dirt and debris from entering the connection between the nut and bolt.

- Easy installation on truck wheels equipped with hubcaps that have holes for wheel nuts.

How does it work?

After tightening the wheel nuts to the correct torque, simply press the Dust Cap covers firmly onto each wheel nut so that the arrows on adjacent indicators face each other. Any slight movement of a nut is immediately visible as a change in the arrow position, allowing a quick visual check. A simple walk around the vehicle before departure ensures all studs are properly tightened.

Additional benefits of using CheckPoint:

The indicators can also signal irregularities in brakes, bearings, or hubs, which result in excessive heat concentrating in the center of the wheel. The heat transfers to the bolts and then to the nuts, causing the indicator tips to bend. This effect is easy to observe, allowing timely action to prevent further damage. This is achieved through a special polymer compound that reacts to high temperatures.

Why choose CheckPoint?

CheckPoint indicators are not ordinary plastic. They are made of a composite material designed to provide high strength and rigidity, while remaining resistant to weather conditions without losing elasticity. This ensures:

- Easy installation on wheel nuts, staying securely in place during driving.

- Repeated use without bending, loosening, or breaking.

Why do wheel nuts/studs loosen?

Common causes cited by transport inspectors include:

- Insufficient tightening (using too low torque).

- Over-tightening or "preloading” the studs, which actually reduces clamping force by overstretching the nut or thread.

- Rapid temperature changes, causing contraction or expansion of materials and loss of clamping force.

- Damaged, worn, or contaminated threads, or bent mounting holes (rust, dirt, metal shavings) affecting torque accuracy.

How can a single loose nut cause a wheel to fall off?

One loose stud creates a domino effect: all vertical, lateral, and centrifugal forces, as well as vibrations, are unevenly distributed. Neighboring bolts loosen under lower loads, which can bend or break studs, shifting the wheel relative to the hub. Additional lateral forces can then cause the studs and nuts to fail completely, resulting in the wheel detaching.

This doesn’t concern me…

Although detailed statistics for truck wheel detachments are limited in Poland, in the United States studies show that weekly there are 40–60 uncontrolled wheel detachments, 20 of which result in serious accidents. About 50% of these cases are caused by loose wheel nuts. These figures clearly demonstrate that failure to systematically check wheel torque poses a real road safety risk.

Entity data

23-114 Jabłonna k/Lublina

Poland

sklep@redats.com