Wheel balancer REDATS W-820

- REDATS W-820 wheel balancer. Wheel size range: 8-35". Automatic.

A premium wheel balancer

Many of your clients might be looking for premium units for their tyre bay.

Here comes a unit that will make a difference to your offer!

The most important information about this balancer:

- made in Italy

- Rim diameter: 8-35”

- balancing time: 5.5 seconds

- Automatic readout of wheel diameter and distance

- Balancing precision 1 g

- Measurement arm with a special handle for weights

- Motorcycle rim calibration

- Car rim calibration

- Static/dynamic balancing

- Optimisation

- Units choice: ounces/grams

- Units: inches/ millimeters

- ALU programs for cars, SUVs and motorcycles

- Hidden weight program

- Multiple operators

- Weight material choice

Just consider how much time your clients can save!

A regular unit balances a wheel in 8 seconds.

With REDATS W-820 it is made in 5.5 seconds.

Ready for large wheels

This is a great choice for those among your clients who want a balancer able to deal with wheels up to 35” (entered manually, in automatic readouts it is 28”). They can use it for wheels of:

- passenger cars

- car-derived vans

- SUV/4x4 cars

Automatic readout of wheel diameter and distance

This unit will measure the distance and diameter of every wheel. Recommend it to your clients as a time-saving solution!

How does wheel parameter readout work?

There is a measurement arm. The operator simply puts it against the rim, so as to read the wheel parameters.

Hidden weight - a solution for premium cars!

Large, nicely looking rims are becoming more and more popular these days.

In wheels sized 21, 22” or even bigger, a larger stripe of weights looks bad. Simple as that.

Recommend this balancer to tyre specialists, so they can offer a better service to their clients.

This unit comes with the SPLIT option. It enables the operator to divide a longer stripe into two - and hide smaller weights behind wheel spokes.

A great solution for bigger rims!

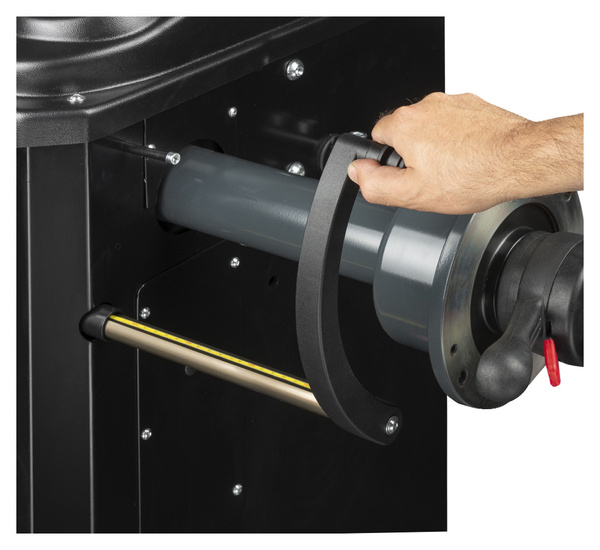

Easy weight application - with a special gauge arm

The operator won’t need to adhere weights manually - a special gauge arm can be of help here.

Simply put the weight on the arm - there is a special handle.

Push it to a chosen position - where the weight should be adhered.

Balancing precision

There is a switch that changes the wheel weight materials:

- Pb,

- Fe,

- Zn

Think this is just an extra option?

Well, don’t forget that zinc/steel weights are a bit lighter than lead ones, hence they might be larger by size.

By selecting the right weight material inside the unit, the operator can be sure they balance the wheel perfectly.

No wobbly wheels. No unbalanced rims.

They can simply choose the weight material and be sure they’ve done all the work properly.

1g precision

Recommend this unit to clients that look for a unit that provides them perfect balancing precision. Without having to correct these. Without any claims from their clients.

2 operators can work at a time

This might be a great choice for those of your clients that want a unit allowing 2 different operators to work at one time. For instance, one operator can stop balancing and go demount the wheel, while the other one balances. It makes the work faster!

Expert's review:

Maciej: Works with wheels up to 35" (manually

Optimisation is for lowering the number of weights to be mounted onto the rim, so that the tyre is located on a rim i a way that the rim's imbalance is equal to tyre's imbalance, which minimizes the wheel imbalance.

Entity data

23-114 Jabłonna k/Lublina

Poland

sklep@redats.com